Caused by contact between the doctor blade and the anilox roll, often due to blade pressure, misalignment or trapped dirt.

It can also result from other types of contamination, such as resins, paper dust and binders.

Spots often appear unnoticed. Dull spots, cloudy streaks or light spots on the ceramic surface.

Often only visible under a certain light - but with great impact on cell volume and pressure consistency.

Recognizable by round, chalky "droplets" that appear in horizontal lines across the roller surface.

These deposits can impede cell volume and interfere with ink flow.

Chances are it's starch deposits from coated substrates such as corrugated cardboard or paper. It accumulates due to insufficient rinsing, drying or prolonged exposure during production.

Often visible as dull, grayish smudges or metallic sheen on the surface of the anilox roll.

In some cases, discoloration or staining may occur, especially in areas of high contact or friction.

Recognizable by thin, straight lines across the anilox roll or visible in the print image - especially distracting in full areas and solid shades.

Corrosion can be recognized by dull, rough or pitted areas on the anilox, often in a "butterfly" shape. These areas cannot be cleaned: the damage is under the ceramic layer, through small cracks.

This guide identifies common problems that can occur with anilox rolls and adversely affect print quality.

Each problem is clearly described, including how it occurs, how it affects production and, most importantly, what can be done from a cleaning perspective. Based on Clean Solutions Group's Total Cleaning Concept, this guide provides targeted and practical solutions to restore and maintain optimal performance of your printing process.

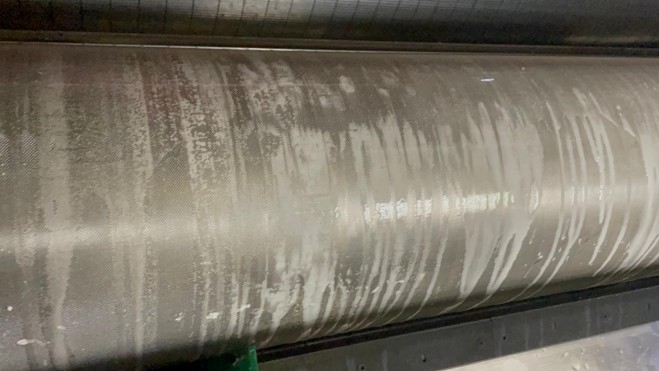

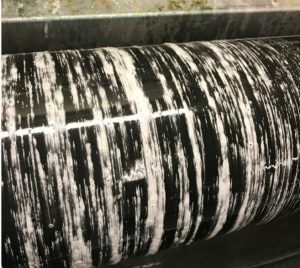

Tiger Stripes appear as fine, parallel lines or scratches on the surface of the anilox roller.

They are often visible under oblique lighting or in areas with a lot of ink.

In the photo, you can clearly see the stripe pattern: the cleaned areas stand out against the still soiled areas, emphasizing the contrast.

Tiger Stripes are caused by contact between the doctor blade and the anilox roller, often due to blade pressure, misalignment or trapped debris. The cause is often difficult to determine, but may be related to:

Perform additional manual cleaning to remove any residue.

Check for physical damage. If damage is visible, consider repair, renovation or replacement.

Flexoclean Anilox Aftercare: our targeted cleaner for periodic manual cleaning.

Use with an appropriate Flexoclean non-abrasive cleaning sponge or cleaning pad.

Always wear proper personal protective equipment (PPE) when working with chemical cleaners.

Visible improvement after targeted manual cleaning. Lines left behind may indicate physical damage rather than contamination.

Repeated Tiger stripes after cleaning the anilox roller?

Check doctor blade alignment, wear and press settings.

Prevention is just as important as cleaning.

Don't forget about cleaning and maintaining the chamber anilox as well, a crucial factor!

In fact, consistent cleaning of the anilox rolls is extremely important in preventing Tiger Stripes from forming.

Spots appear as irregular, cloudy or hazy spots on the grid surface.

They often vary in size and shape, and can be difficult to detect without oblique light or close inspection.

In this photo, several diffuse light spots are visible on the roll, indicating residue or accumulation affecting cell volume and print consistency.

Accumulation of dried ink, coating residue or crystallization of cleaning products in the cells or on the roller surface.

Often caused by inadequate rinsing or ineffective daily cleaning.

Perform additional manual cleaning with a suitable detergent and sponge to remove stubborn residue. Visually inspect the roller after cleaning.

Flexoclean Anilox Aftercare or a compatible cleaner (depending on ink type). Use in conjunction with a non-abrasive cleaning sponge.

After manual cleaning, the surface should look smooth and stain-free as shown in the picture.

If stains persist, repeat the process or contact technical support.

Prevent future staining by rinsing thoroughly daily and using soft water whenever possible.

Recognizable by round, chalky "droplets" that appear in horizontal lines across the roller surface.

These deposits can impede cell volume and interfere with ink flow.

Usually caused by calcium buildup from hard water, ink components or inadequate rinsing after cleaning. Calcium deposits can also occur due to chemical interactions between cleaning agents and mineral residues.

Perform additional manual cleaning using a targeted product that dissolves mineral buildup.

Clean Solutions Group has Flexoclean Anilox Aftercare specifically for this problem. Use the product in conjunction with a non-abrasive cleaning sponge or cleaning pad.

During treatment, lime deposits should visibly dissolve and the surface should regain a uniform appearance.

After manual cleaning, the surface should look smooth and stain-free as shown in the photo below.

Persistent buildup may indicate water quality problems or lack of cleaning frequency. If the problem persists, repeat the process or contact our technical support.

Prevent scaling by using softened water and rinsing thoroughly after each cleaning cycle.

Recognizable by round, chalky "droplets" that appear in horizontal lines on top of each other

the rolling surface.

Starch residue comes from coated substrates such as corrugated cardboard or paper.

It builds up over time due to inadequate rinsing, drying or prolonged exposure during production runs.

Perform additional manual cleaning to remove the starch layer. Ensure a proper drying and rinsing routine in the future.

For this particular anilox issue, use the Starch Buster in conjunction with a Flexoclean sponge or suitable cleaning pad.

Visible improvement within about 15 minutes of cleaning.

Repeated cleaning may be necessary for severe deposits.

After 15 minutes of cleaning

Regular, light manual cleaning helps prevent the accumulation of starch

between deep cleaning intervals.

Often visible as dull, grayish smudges or metallic sheen on the surface of the anilox roll.

In some cases, discoloration or staining may occur, especially in areas of high contact or friction

Aluminum residue can come from mechanical parts, substrates or friction with metal components during production. Inadequate rinsing or incompatible cleaning agents can also contribute to buildup.

Perform additional manual cleaning with an aluminum-specific remover.

Inspect the roller and nearby components for sources of contact with aluminum.

Clean Solutions Group has Flexoclean Alu Remover specifically for this problem.

Clean Solutions Group has Flexoclean Alu Remover specifically for this problem.

Visible improvement within about 15 minutes of cleaning.

Repeated cleaning may be necessary for severe deposits.

Chemical reaction during cleaning process Result after 15 minutes

Regular inspection and proper alignment of metal parts can help prevent aluminum-related contamination.

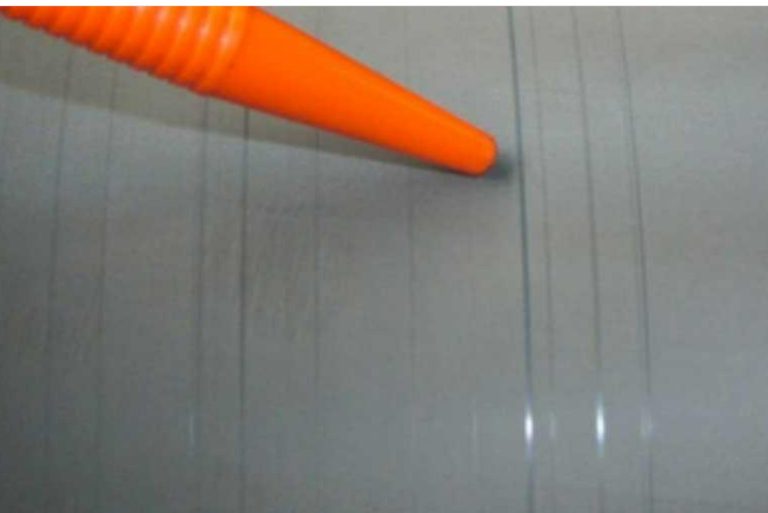

Thin, parallel lines or stripes running across the print or anilox roll.

The first image shows fine, linear marks on the roll surface.

The second image shows how these stripes affect print quality in solid areas.

Score lines - also called kerf lines in Dutch - are usually caused by:

Regular maintenance and replacing the squeegee blade on a regular basis helps to prevent streaking.

Clean the blade and chamber thoroughly with the appropriate daily cleaner to remove dried ink or coating residue. If you would like advice on which cleaning agent works best for your situation, feel free to contact us.

Use a new squeegee blade if wear is visible.

A daily cleaner helps restore smooth ink transfer and eliminates streaks caused by contamination behind the blade.

Which product is best for daily cleaning in your situation depends on a number of factors, such as type of ink.

Our R&D department can advise you on this.

Corrosion appears as dull, rough or pitting on the grid surface.

It often takes the form of a "butterfly," a dark core (the damaged area) with a lighter area around it, similar to wings.

In the photos, the affected areas are circled in red. These areas cannot be cleaned, they are permanent damage and not surface contamination.

Caused by prolonged exposure to ink, moisture or chemical residues left on the roller.

Poor rinsing, harsh cleaning agents or long machine downtime with product residues can cause corrosion under the surface.

Unfortunately, corrosion is not cleanable.

Remove the roll from production and consult your local CSG troubleshooter for further evaluation.

Unfortunately, corrosion is not cleanable.

Remove the roll from production and consult your local CSG troubleshooter for further evaluation.